- |

- RAFFLES

Alkaline Electrolyzer Products

The existing electrolyzer products of CIMC GH2 are mainly alkaline electrolyzers. The existing three types of water electrolyzer hydrogen production products can match various hydrogen production scenarios, the system is stable and reliable, with the optimal unit hydrogen production cost LCOH as the ultimate goal, can be widely used in petrochemical, chemical, electric power, iron and steel metallurgy, transportation, other manufacturing fields. Currently, it mainly includes the following three series of products:

1. Large-scale Electrolyzer CIMC-GH Series

CIMC-GH series of CIMC-GH series, a lightweight large electrolyzer, has been commercialized with a practical hydrogen production capacity of 1500Nm3/h. It has the following performance advantages:

- Lightweight: Current density 4000A/m2, cell number about 230. electrolyzer body is only about 40 tons.

- High stability: the pole frame is thicker than other similar products in the industry, the circulation cross-sectional area of the electrolytic chamber is large, the electrolyte circulation cooling is sufficient, so that the temperature consistency of each electrolytic chamber is good, and the thermal expansion and cold contraction are uniform. It will not allow the temperature of individual small chamber tank to be too high, resulting in deformation and failure of electrolyzer.

- Long life: the electrolyzer is light in weight (less than 30 tons) and the sealing gasket is light in load, which makes the overhaul cycle life of the electrolyzer longer and the stability reaches more than ten years.

2. SDQ hydrogen production series: frame electrolyzer, used in large-scale hydrogen production scenarios

SDQ series hydrolysis hydrogen production equipment, suitable for large-scale hydrogen production stations.

The maximum hydrogen production capacity of a single set is 1500Nm3/h; It can be combined into multiple sets for parallel operation at the same time.

The electrolyzer adopts bipolar pressure filter type structure, and the insulation sealing gasket has strong sealing performance.

Gas-liquid processor for the frame combined structure, simple process, easy installation, operation, maintenance.

Automatic microcomputer control, high degree of automation, remote centralized management, man-machine intelligent interface, easy to operate, safe and reliable.

The purity of hydrogen after purification reaches 99.9995%, oxygen purity reaches 99.2%.

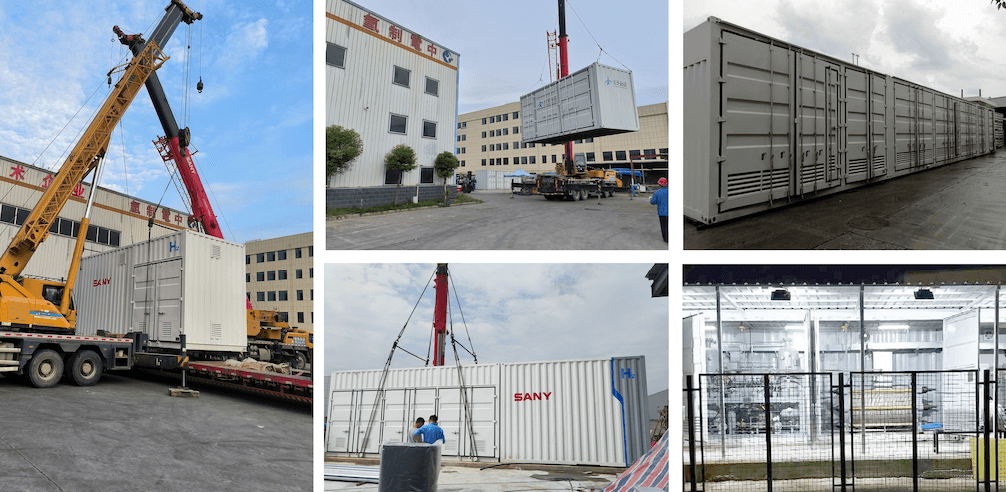

3. Container Hydrogen Production (CSDQ) Equipment

Highly integrated, it is suitable for the scene of integrated station of manufacturing, storage and hydrogenation.

The CsDQ series is an independent hydrogen production station installed in a container, integrating electrolyzer, gas-liquid processor, purification equipment, control cabinet, rectifier cabinet and transformer.

There is no need for construction installation, and it can be moved. Users only need to access water and electricity to produce hydrogen, which can be as high as 500Nm°/h. The purity of hydrogen can reach 99.999%.

The system can be installed on any site where hydrogen is produced.

CsDQ equipment has been assembled and tested prior to delivery, simplifying installation at the customer's site, making it easy to operate, and ensuring reliability and safety.

4. CHE hydrogen production series: ready-to-use, suitable for on-site hydrogen production scenarios

CHE series is a type of ready-to-use hydrogen production equipment. The hydrogen production equipment is zero stored in the hydrogen process and installed near the hydrogen production equipment. There is no need to build a hydrogen production station.

The equipment is small in size, light in weight, fully automatic and unattended, with hydrogen output of 0.5Nm2~40Nm°/h and hydrogen purity of 99.999%.。