- |

- RAFFLES

Sany Heavy Industry Hydrogen Generation & Refueling Station

In 2022, the 200Nm³/h containerized hydrogen production equipment was delivered to Sany Heavy Industry and successfully put into use. The equipment can achieve a hydrogen purity of 99.999%, mainly used for hydrogen production and fuel cell heavy trucks and other vehicles.

- 1. The container equipment has the lowest DC power consumption, to 4.2kWh/m³.

- 2. Quickly start-up: standby start-up within 30 seconds.Cold start-up within 30 minutes. Wide range of adjustment;load range between 20% and 100%.

- 3. Achieve zero emission, 100% recovery and recycling of all discharged pure water; Full utilization of zero emission of regenerated hydrogen; Waste lye is recycled.

Qingdao Hydrogen Generator Project

Qingdao Fusion New Material Technology Co., Ltd. MINI LED backplane project hydroelectrolysis hydrogen production equipment, installed in the hydrogen production station area of Qingdao Fusion New Material Technology Co., LTD. The project is a turnkey project in the hydrogen production station area. The total hydrogen production capacity of this equipment is 500Nm³/h (a single 250Nm³/h standby), the purity of hydrogen is as high as 99.999%. The advanced control system of hydrogen production equipment provided by our company has a high degree of automation, strong reliability, and unattended, which is widely praised by customers.

Hunan Huaihua 3 sets of 200 m³/ hH2 electrolyzer project

Hunan Huaihua cover plate project is three sets of 200 m³/ hH2 hydrogen production equipment, the three devices adopt the design concept of one thousand thousand devices, three sets of parallel, in which the post-processing system and the electrolyzer correspond one by one (to meet the production requirements). The hydrogen purity of the equipment is 99.999%, and the outlet pressure is greater than or equal to 1.6MPa, which provides protective gas for the production line. After the delivery of the goods, the company will assign a special project manager to the customer site, handle the construction approval and related safety construction procedures according to the requirements of the local government authorities, and coordinate the on-site work of civil construction and equipment installation.

Xi 'an Aerospace containerized water electrolysis hydrogen production device

According to the customer's research requirements, the company delivered customized containerized hydrogen generator equipment to Xi 'an Aerospace Sixth Academy for the research of a new generation of aerospace hydrogen fuel engine.

This kind of customized containerized hydrogen generator equipment is mainly suitable for all kinds of universities and research institutions without site conditions. The company has equipped a number of proprietary technologies in this project to maximize the efficiency of hydrogen production equipment. Including automatic caustic soda back system, test evaluation software, etc. Assist manufacturers to make better use of our hydrogen production equipment for product testing, complete data recording.

In addition to the delivery of hydrogen production equipment, the company also provides hydrogen production technology training for aerospace personnel, which is the beginning of the company's maintenance and control business.

Korea PEM electrolyzer aftertreatment system project

The company is the designated supplier of HTS alkaline electrolyzer in Korea. This project of PEM hydrogen production equipment reprocessing system is the first cooperation between our company and HTS in Korea, and also the first achievement completed after the establishment of reprocessing department of the company, which has milestone significance for the company's hydrogen production equipment reprocessing business segment. This set of after-treatment system adopts the company's Shanghai control system, which has a high degree of automation, unattended in the normal production process of hydrogen, clean and pollution-free, no three wastes discharge, and high reliability.

Mianyang electronic project

Mianyang Electronics Project is a 150m³/hH2 traditional hydrogen production station equipment, equipped with split electrolyzer, hydrogen production frame, purification frame and hydrogen production accessories. 150 m³/hH2 belongs to medium and large equipment, which needs to be fixed before capping the traditional hydrogen production station. The coordination degree of civil construction and equipment installation site is required to be high, our company successfully completed this turnkey project, and established a good long-term supply relationship with Dongxu Group from this beginning.

Huadian Heavy Industry Luding Distributed Green Hydrogen Project

The first Pilot project covering full-life-cycle from hydrogen generation till hydrogen application in China, integrating alkaline electrolysis system,solid-state hydrogen storage, liquid hydrogen storage and fuel cell application. It relies on the test platform built by Huadian Luding Hydropower Station to carry out demonstration tests and technical research. The company is responsible for the following scope of work in this project:

- Provide a complete set of 100 Nm³/h modular containerized hydrogen generators of alkaline electrolyzer.

- Provide on-site commissioning services and Installation Guidance.

- Provide equipment follow-up operation and maintenance services

At the end of 2021, the project "first bottle of green hydrogen was released". Huadian Heavy Industry Luding Hydrogen Production Project Department officially received the hydrogen quality inspection report issued by the third-party testing agency, marking a phased victory in the commissioning of the whole system of hydrogen production equipment undertaken by China Huadian Group's renewable energy hydrogen production, energy storage and hydrogen energy comprehensive utilization technology research project.

Sino Magnetics Technology Co.,Ltd.4000A/㎡ hydrogen production project

In 2020, the company provided 4000A/㎡ current density of 20Nm³/h hydrogen production equipment for Sino Magnetics Technology Co.,Ltd. successfully put into operation, the equipment in the purity of hydrogen up to 99.999%, only requires ultra-low power consumption. Through the company's unmanned electronic management of equipment, automatic valve interlocking pressure retention, multiple sets of equipment parallel module system, Sino Magnetics Technology Co.,Ltd. shares can completely realize non-stop production, and any unexpected situation will not affect the operation of hydrogen production equipment. The project saved investment and operation and maintenance costs for customers, and was highly recognized by customers, and repeatedly purchased the company's equipment.

Korea 4000A/㎡ low power consumption hydrogen production project

In 2021, the company provided 4000A/㎡ hydrogen electrolyzer for the Korean Group, which can produce 40Nm³ hydrogen per hour and the purity of hydrogen can reach 99.999%. The 4000A/㎡ electrolyzer is a product developed by the company through industry-university-research cooperation with the College of Materials Science and Technology of Yangzhou University. This set of high current electrolyzer is also the second commercial operation of 4000A/㎡ of our company. At present, we are actively participating in various research and development projects to develop new membrane electrodes and manufacture electrolytic cells with lower energy consumption.

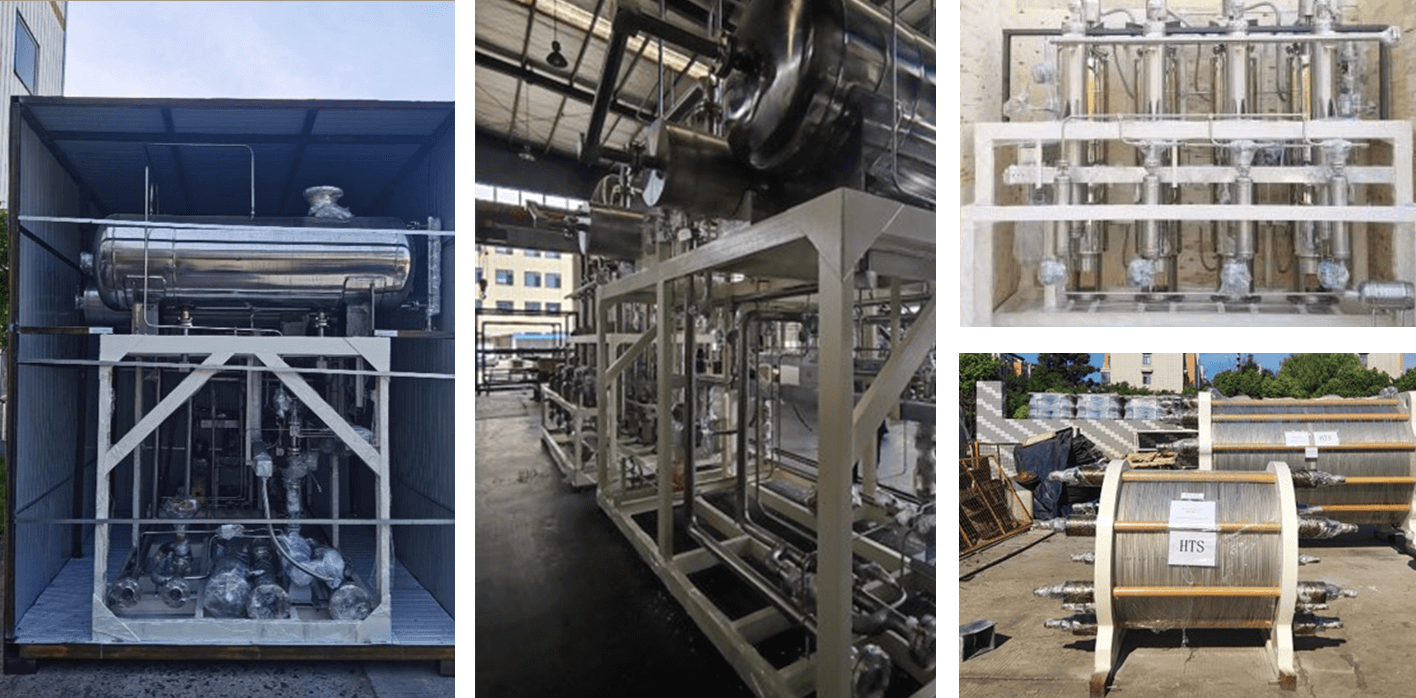

Korea multiple sets of hydrogen production equipment export project

The company has delivered several sets of hydrogen production equipment for Korea Hydrogen Energy Company over the years. With the excellent quality of products and professional technical services, we have been highly recognized by customers, and have purchased hydrogen production equipment from the company for hydrogen energy projects for many times. In 2022, our company has delivered two sets of hydrogen energy equipment(pictured)to South Korea , including one set of 200m³/h(current density 2000 A/㎡) complete equipment and one set of 50m³/h (current density 4000 A/㎡) complete equipment. The above two sets of equipment will be used in photovoltaic hydrogen production scenarios.

containerized hydrogen generator for Hydrogen-enriched natural gas project in Ukraine

This set of containerized hydrogen generator equipment is applied to the Ukrainian natural gas hydrogen blending project. 15% hydrogen is added into natural gas, which changes the combustion characteristics of natural gas and is conducive to better combustion of hydrogen. The hydrogen output of the equipment is 200m³/h, the purity of hydrogen is 99.999%, and the hydrogen pressure is 1.6MPa. It is the largest single set of containerized hydrogen generator equipment in China at the time of delivery.

Oil hydrogenation project in Uzbekistan

This set of containerized hydrogen generator equipment is applied to oil processing enterprises in Uzbekistan, which saturates double bonds of oil through oil hydrogenation technology. It is an effective means of oil modification and has very high economic value. The hydrogen output of the equipment is 100m³/h, the hydrogen purity is 99.999%, and the hydrogen pressure is 1.6MPa; The on-site commissioning and putting into production is smooth, and it is running stably at present.