- |

- RAFFLES

Start-up Period

Alkaline electrolyzer core team established

Officially started the first generation of alkaline electrolyzer research

Design and manufacture of the first generation of mastoid structure bipolar plates

Focus On Technology

Design and manufacture the first generation of integrated diaphragm gaskets

Plant put into operation with hydrogen production line.

Huai 'an polysilicon production 80m³/h hydrogen production equipment

Craftsmanship Spirit

Designed and manufactured the first generation of mastoid structure electrolyzer with current density of 2000A/m2 for export to DPRK CHE project

Design and manufacture the first generation of plate mesh bipolar plate

Obtained 1 patent of "Hydrogen exhaust gas recovery Device";

And 3 utility model patents such as "solar photovoltaic hydrogen production equipment"

Xiamen Jimei Semiconductor Project

Introduce and absorb foreign advanced technology, design and manufacture the first generation of sheet metal weldless electrolyzer current density 2500A/m2

Signed a contract with Dynamic College of Yangzhou University, and set up an industry-university-research cooperation base.

Officially became a member of China Industrial Gas Industry Association.

Become the hydrogen production equipment production base of AVic International.

Export multiple sets of sheet electrolyzers to India

First won the title of national high-tech enterprise.

Imported hydrogen production equipment domestic replacement project

Research and development of split type modified sealing gaskets

Obtained 2 utility model patents such as "electrolyzer"

Application of PPS based non-asbestos diaphragm

Yiyang power plant original imported equipment domestic replacement

Coordinated Development

Developed and put into use the second generation of board mesh bipolar plate

Laicheng Power Plant Project of Huadian Group

Obtained 5 utility model patents such as "Electrolyte self-circulating medium pressure hydroelectricity hydrogen production System"

Design and manufacture tandem electrolyzer (one plus one minus)

Won the title of national high-tech enterprise again

Vietnam Helikang hydrogenation is the first complete set of hydrogen production equipment exported by our company.

Design and manufacture electrolyzer with current density of 3000A/m2 through industry-university-research cooperation

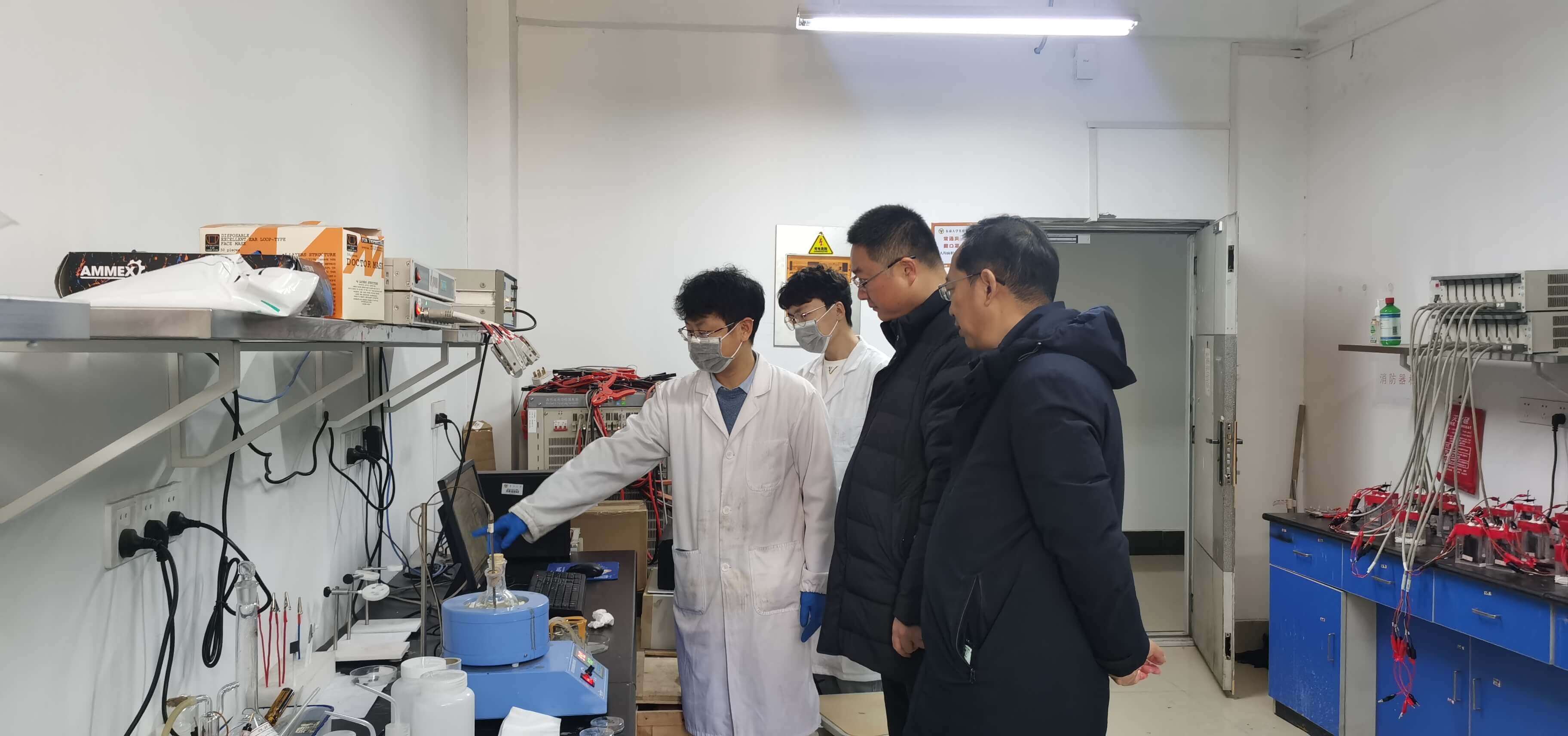

In cooperation with Southeast University, it has set up an industry-university-research base for renewable energy and hydrogen technology.

Obtained the quality system certification certificate.

Ya 'an silicon Dioxide 300m³/h hydrogen production equipment

Developed and put into use the third generation of board mesh bipolar plate

Luoyang polysilicon hydrogen production of 300m³/h

Design and manufacture CLP proprietary composite electrode electrolyzer

Current density 3500A/m2 Kone 50m³/h hydrogen production equipment for germanium industry

Design and manufacture electrolyzer with current density 4000A/m2 through industry-university-research cooperation

Export 65Nm³/h container-type equipment from Egypt

Hydrogen production equipment for electrolyzer with current density of 3000A/㎡ in Zhanjiang Power Plant

Obtained 1 patent of "A hydrogen production device and hydrogen production Method for alkaline solution electrolysis"

Won the title of National high-tech enterprise again.

Uzbekistan oil processing enterprise container equipment

Hydrogen production equipment with current density of 3500A/㎡ in Hami Power plant

Major breakthroughs have been made in key technologies of 1000 cubic meters of basic hydrogen production

It has obtained 11 utility model patents such as "An electrolyzer with good sealing Effect".

Registered an international top-level domain name and an international domain name.

Accumulate And Develop Gradually

Design and manufacture the first set of Transone series electrolyzer

4000A/㎡ current density 20Nm³/h hydrogen production equipment of Zhongci Technology Co., Ltd.

SDQ-40/3 hydrogen production equipment of Hydrogensong Technology Development Co., Ltd.

Declare 1 patent for "A modular electrolyzer group".

18 utility model patents including "A hydrogen production system" were declared.

Cooperate with universities to launch joint research and development of electrolyzer with current density of 6000A/m2.

Design and manufacture 1000Nm³/h electrolyzer

Ukrainian gas and hydrogen mixing 200m³/h container hydrogen production equipment

100m³/h container hydrogen production equipment of China Huadian Group

Cultivate Deeply And Carefully

In 2022, it was wholly acquired by CIMC and officially became a wholly-owned subsidiary of CIMC offshore Plate hydrogen production equipment, and Yangzhou CIMC changed its name to CIMC. Based on the strong manufacturing gene of CIMC, the team of CIMC has been ready to take off.

The 1000 cubic alkali cell has been commercialized, and 1500Nm³/h electrolyzer has been designed and manufactured.

And won the title of national high-tech enterprise again.

Huaihua Cover plate three sets of 200 m³/Hh2 hydrogen production equipment

Sany Heavy Industry Co., Ltd. Changsha Branch with maximum daily production of 500kg hydrogen with the integration of production, storage and processing of Sany Heavy Industry

Two utility model patents, including One Kind of electrolyzer, were approved.

Join Us For A Better Future